Alfalfa Dryer

Alfalfa Dryer Introduction

Alfalfa is rich in protein, mineral elements and carbohydrates, especially high in crude protein. However, the moisture content of the alfalfa is very high, so it is not suitable for direct storage. The forage drying equipment can dry the fresh alfalfa with water content of 60-70% to less than 12%, while maintaining the nutrients in the fresh grass, and improving the deep processing of forage. The whole drying process is pollution-free to the forage, which ensures the quality and taste of the forage, improves the storage and utilization rate of alfalfa, and facilitates transportation and feeding.

Advantages of Alfalfa Drying Machine

1. The hot air temperature is set according to the needs of the forage, and the forage does not change color after drying.

2. The frequency conversion speed regulating motor is adopt to control the drying time according to the moisture content of the grass, so as to maximize the drying efficiency.

3. The whole forage drying system adopts electric centralized control, with high degree of automation and convenient operation.

4. Equipped with perfect dust removal device, ensuring good sealing performance, and no dust overflow.

5. It can be combined with subsequent processes such as crushing, mixing, pelletizing and packaging to improve the deep processing of forage.

Forage Grass Dryer Wide Application

The grass dryer is suitable for drying forage such alfalfa, green bristlegrass, elephant grass, rice straw, timothy grass, mulberry leaves, straw, ryegrass, oat grass, grain amaranth, bamboo grass, clover, tree leaves, pitcher grass and other biomass fiber. The drying process does not pollute the forage, ensures the quality and taste of the forage, improves storage and utilization, and is convenient for transportation and feeding.

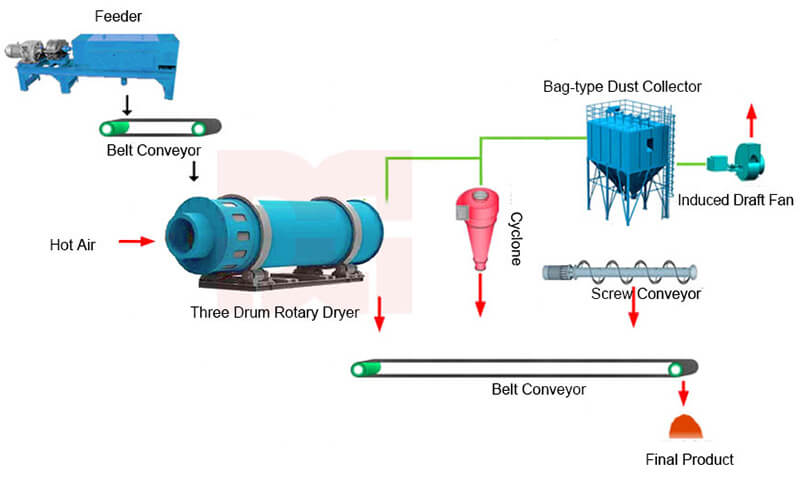

Forage Grass Dryer Working Principle

The forage is sent into the drum by the conveyor for downstream drying. It is continuously lifted and scattered under the action of inner lifting board and moves in a spiral way to realize the heat exchange between the grass and hot air. The dried grass moves quickly to discharge from the drum under the action of wind. The wet grass that does not achieve the drying effect cannot move quickly because of its own weight. It will be fully dried in the drum until meeting the moisture requirements for the materials. Then it is discharged by the screw conveyor.

Forage Grass Dryer Working Video

Alfalfa Dryer Technical Parameters

Model | DDSG2010 | DDSG 2210 | DDSG 2510 | DDSG 2512 | DDSG 2912 |

Capacity (t/d) | 63.5-144.5 | 67.5-154.0 | 83.5-193.0 | 100-227.0 | 120.0-268.0 |

Vaporization (t/h) | 1.850 | 1.976 | 2.427 | 2.912 | 3.432 |

Initial moisture (%) | 35~60 | 35~60 | 35~60 | 35~60 | 35~60 |

Final moisture (%) | 12~15% | 12~15% | 12~15% | 12~15% | 12~15% |

Drying temperature | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 |

Power(kw) | 78 | 85 | 110 | 125 | 135 |

Weight (kg) | 25000 | 27000 | 35000 | 38000 | 43500 |

Plant area (㎡) | 8m×18m | 10m×18m | 10m×18m | 10m×20m | 10m×22m |