Straw Dryer

Straw Dryer Machine Introduction

The straw dryer machine is a new type agricultural drying equipment for the reuse of crop straw. It is mainly used for drying agricultural cellulose materials, like corn stalk, rice straw, wheat straw, sorghum straw, wood chips, etc. We can optimize the drying technology according to the characteristics of each biomass material. The three-layer straw dryer has large output, high efficiency, low energy consumption and small floor area. It can save 30-50% energy compared with ordinary dryer, which can save more energy and drying costs.

Structure Advantages of Straw Dryer Machine

* Adopt unique double-layer lifting board, ensuring the good drying effect.

* Equip with unique sealing device and heat preservation system, effectively reduce the energy consumption of the drying system.

* The scraper loader is adopted with stepless variable speed transmission, and the feeding amount can be conveniently adjusted according to the moisture content of the material.

* Temperature sensors and digital display instruments are installed to achieve good drying effect and ensure the safe operation.

* The whole drying system adopts electric centralized control, and the temperature of hot air is automatically adjusted, high degree of automation and easy operation.

Wide Application of Straw Dryer Machine

Straw dryer is widely used for drying agricultural cellulose materials such as corn straw, soybean straw, cotton straw, wheat straw, sorghum straw, wood chips, shavings, sawdust, ginkgo leaves and mulberry leaves. Besides, it can also be used for distiller’s grains, pasture, apple pomace, compound fertilizer and other materials with poor dispersibility and high water content.

Crop Straw Dryer Working Principle

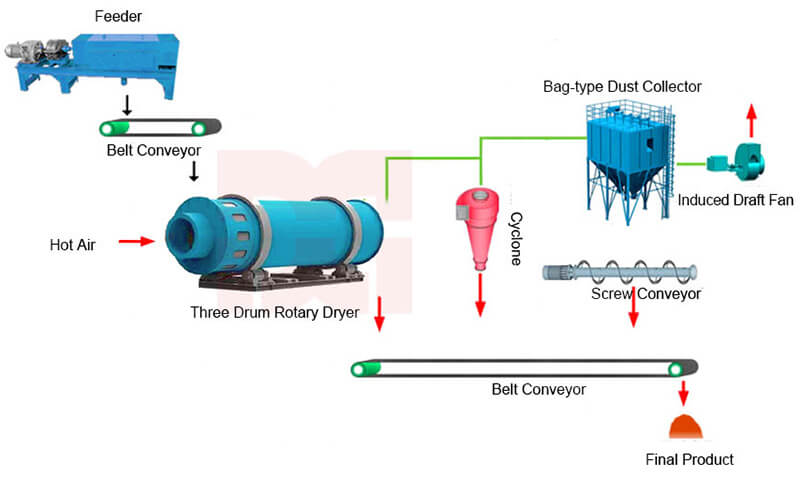

The straw dryer adopts concurrent flow drying to realize the heat exchange between hot air and wet straw. The wet straw enters the straw dryer from the feeding bin through the belt conveyor or bucket elevator. Under the combined action of the screw propulsion force, guiding plate and the gravity of the material itself, a uniform material curtain is formed through the material lifting plate. The hot air is fully contacted with the material curtain to achieve full heat exchange. Finally, the dried material is discharged out through the sealed discharge screw conveyor, and then manually packaged. The waste gas is discharged into the atmosphere after being treated by the dust remover.

Straw Dryer Working Video

Crop Straw Dryer Technical Parameters

Model | DDSG2010 | DDSG 2210 | DDSG 2510 | DDSG 2512 | DDSG 2912 |

Capacity (t/d) | 63.5-144.5 | 67.5-154.0 | 83.5-193.0 | 100-227.0 | 120.0-268.0 |

Vaporization (t/h) | 1.850 | 1.976 | 2.427 | 2.912 | 3.432 |

Initial moisture (%) | 35~60 | 35~60 | 35~60 | 35~60 | 35~60 |

Final moisture (%) | 12~15% | 12~15% | 12~15% | 12~15% | 12~15% |

Drying temperature | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 |

Power(kw) | 78 | 85 | 110 | 125 | 135 |

Weight (kg) | 25000 | 27000 | 35000 | 38000 | 43500 |

Plant area (㎡) | 8m×18m | 10m×18m | 10m×18m | 10m×20m | 10m×22m |