Sand Dryer

Sand Dryer Introduction

Sand dryer is a three drum rotary drying equipment, mainly used for the dehydration and drying of particle materials with large moisture content and large specific gravity. The final material moisture can reach below 0.5-1%, which fully meets the moisture requirements of various industries. The most commonly used drying materials are yellow sand used in the dry powder mortar industry and sand of various specifications used in the foundry industry.

Advantages of Sand Drying Machine

1. Simple structure, small volume, convenient operation and maintenance.

2. Made of wear-resistant manganese plate, 3-4 times more wear-resistant than ordinary steel plate.

3. No air leakage, completely solving the sealing difficulties.

4. The discharge temperature is less than 60 ℃, so the dried sand can be directly fed to the warehouse without cooling.

5. Multiple heat sources for your selection, such as coal, biomass, oil, gas and other fuels.

Sand Dryer Machine Application

Three Drum Sand Dryer Structure

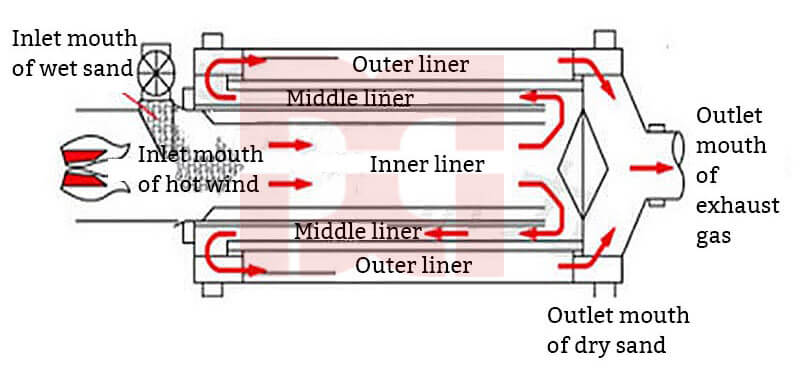

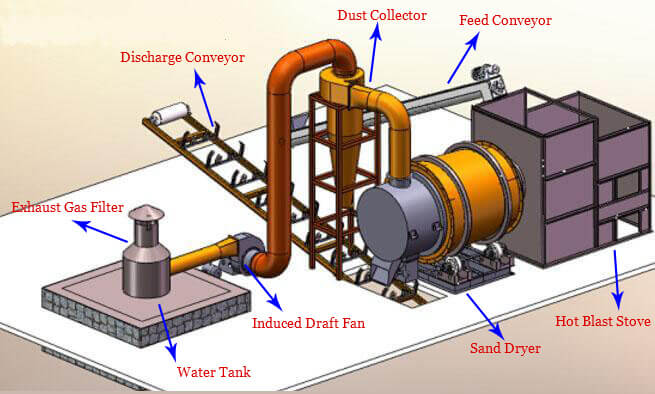

The sand dryer is mainly composed of three-layer cylinder, induced draft fan, high-speed dispersing device, lifting plate, self cleaning device, transmission device, conveying equipment, hot air equipment, reducer, support device and sealing device.

Sand Dryer Working Site

Sand Dryer Technical Parameters

Model | Capacity(T/h) | Coal consumption (drying 1t materials) | Total power | ||

River sand | Fly ash | Slag | |||

Φ2.0×2 | 4-5 | 2-3 | 3-5 | 12-14 | 5.5kw |

Φ2.0×4 | 8-12 | 4-6 | 8-10 | 12-14 | 3kw×2 |

Φ2.0×5 | 12-15 | 6-7 | 10-13 | 10-12 | 4kw×2 |

Φ2.2×4.5 | 14-18 | 7-9 | 12-15 | 10-12 | 5.5kw×2 |

Φ2.5×6 | 23-28 | 10-13 | 20-22 | 10-12 | 5.5kw×4 |

Φ2.8×6 | 30-35 | 15-18 | 25-30 | 10-12 | 5.5kw×4 |

Φ3.0×6 | 35-40 | 18-20 | 32-35 | 8-10 | 7.5kw×4 |

Φ3.0×7 | 40-45 | 20-25 | 35-40 | 8-10 | 7.5kw×4 |

Φ3.2×7 | 45-50 | 25-30 | 40-45 | 8-10 | 11kw×4 |

Φ3.2×8 | 50-55 | 30-35 | 45-50 | 8-10 | 11kw×4 |

Φ3.6×8 | 60-70 | 35-40 | 60-65 | 6-8 | 15kw×4 |

Φ3.8×9 | 70-80 | 40-45 | 70-75 | 6-8 | 15kw×4 |

Φ4.0×10 | 90-100 | 45-50 | 80-90 | 6-8 | 18.5kw×4 |

Φ4.2×8.5 | 80-100 | 45-60 | 80-90 | 6-8 | 18.5kw×4 |

(The moisture is: 15%~1%) | |||||