Pomace Dryer

Pomace Dryer Introduction

The pomace dryer can quickly evaporate the water in the fruit dregs through high temperature heat transfer. The wet fruit dregs with a moisture content of 60-80% can be quickly dried to about 10%, greatly reducing the weight of the fruit residue, reducing the volume to one-third to one-fifth of the original, which is convenient for transportation and storage. The dried pomace can be used not only as feed for livestock breeding, but also as fertilizer for mushroom cultivation.

Main Characteristics of Fruit Dregs Drying Machine

♠ Adopt stepless variable speed transmission, the rotating speed of the drum can be adjusted according to the different moisture content of the materials, so as to achieve the ideal drying effect.

♣ The fruit residue dryer adopts a novel and unique sealing device, and is equipped with an effective thermal insulation system.

♥ A powerful disperser is set in the drum of the fruit dregs dryer, effectively solve the problems of sticking and caking of fruit dregs in the drying process.

♦ The whole fruit residue drying system adopts electric centralized control, with high degree of automation and convenient operation.

♠ After the drying section, subsequent sections such as crushing, mixing, pelletizing and packaging can be connected to produce fruit residue feed pellets.

Wide Application of Pomace Drying System

The pomace drying system can quickly convert fruit dregs resources with high moisture content, high sugar content and easy adhesion into high protein feed. The complete fruit dregs dryer production line is applicable for processing olive pomace, apple residues, spent grain, bean dregs, sugar beet pulp, bagasse, etc.

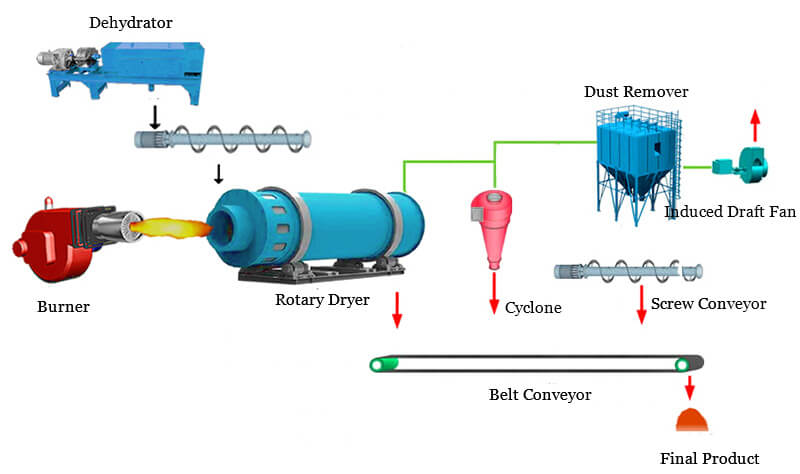

Pomace Dryer Machine Working Principle

The wet fruit dregs with a moisture content of about 80% can be dehydrated mechanically to remove some free water, and then transported to the drying drum for downstream drying. The fruit residue is constantly lifted and dispersed in the drum, moving forward in a spiral way. The built-in dispersing device can fully mix, disperse and crush materials, fully exchange heat between materials and hot air, and rapidly evaporate and vaporize water. The dried materials are discharged from the drum rapidly under the action of hot air. The wet materials that do not achieve the drying effect cannot move quickly due to their own weight. The materials will be fully dried in the drum until achieve the drying effect. The dried materials are conveyed to the packaging system by the screw conveyor.

Fruit Residue Dryer Working Video

Fruit Dregs Dryer Technical Parameters

Model | Capacity | Power | Floor Area(㎡) |

DDGZ1409 | 300kg/h | 28kw | 120㎡ |

DDGZ1412 | 600kg/h | 30.6kw | 135㎡ |

DDGZ1415 | 800kg/h | 32.7kw | 150㎡ |

DDGZ16165 | 1300kg/h | 40.2kw | 190㎡ |

DDGZ2212-3 | 2300kg/h | 64.4kw | 220㎡ |

DDGZ29135-3 | 4500kg/h | 116kw | 350㎡ |