Sawdust Dryer

Wood Sawdust Dryer Introduction

Wood sawdust dryer is a triple pass drying equipment specially designed and manufactured for drying wood processing by-products, such as wood chips, wood flour, sawdust, wood bran, wood shavings and other biomass fuels. We can also optimize the drying technology according to the characteristics and production needs of each biomass material. The sawdust rotary dryer combines the characteristics of airflow dryer, and has the advantages of energy conservation, environmental protection, high efficiency and small floor space.

Sawdust Dryer Machine Features

1. Adopt special internal structure design to reduce heat loss, and the drying efficiency reaches 90-95%.

2. The required drying time and final moisture can be adjusted according to users’ requirements.

3. The patented four-wheel drive device is adopted to ensure the stability and adjustability of the drum, and also protect the working condition safety of the drive motor.

4. The discharge system is fully sealed, which effectively prevents material from being drawn away due to air leakage, and also prevent dust from flying.

5. The outlet temperature is low, which can prolong the service life of dust removing device, and the next process can be carried out continuously.

Wood Sawdust Dryer Wide Application

The sawdust dryer is widely used for drying small particle loose materials in chemical industry, light industry, agriculture, food industry and feed industry. It is applicable for drying wood chips, sawdust, bagasse, wood shavings, crop straw, spent grain, fruit dregs, bean dregs, as well as potato vines and peanut vines.

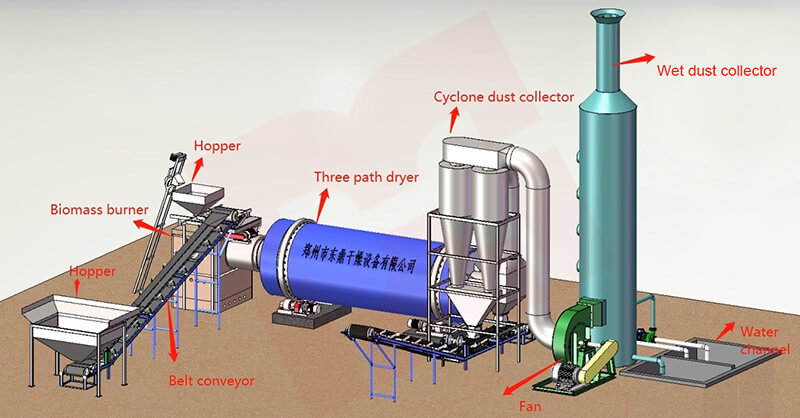

Complete Wood Sawdust Drying System

The complete sawdust drying system is mainly composed of hot air stove, closed air feeder, belt conveyor (optional), screw feeder, rotary drum dryer, fan, cyclone, closed fan, etc. The sawdust dryer combines the advantages of air flow dryer and drum dryer, with good working efficiency, low investment cost and small floor area.

Sawdust Dryer Working Video

Sawdust Dryer Technical Parameters

Model | DDSG2010 | DDSG 2210 | DDSG 2510 | DDSG 2512 | DDSG 2912 |

Capacity (t/d) | 63.5-144.5 | 67.5-154.0 | 83.5-193.0 | 100-227.0 | 120.0-268.0 |

Vaporization (t/h) | 1.850 | 1.976 | 2.427 | 2.912 | 3.432 |

Initial moisture (%) | 35~60 | 35~60 | 35~60 | 35~60 | 35~60 |

Final moisture (%) | 12~15% | 12~15% | 12~15% | 12~15% | 12~15% |

Drying temperature | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 |

Power(kw) | 78 | 85 | 110 | 125 | 135 |

Weight (kg) | 25000 | 27000 | 35000 | 38000 | 43500 |

Plant area (㎡) | 8m×18m | 10m×18m | 10m×18m | 10m×20m | 10m×22m |