Fly Ash Dryer

Fly Ash Dryer Machine Introduction

Fly ash is the solid waste left in the furnace after coal combustion, which is one of the industrial waste residues with large emissions at present, and also one of the main components of haze formation. However, after drying, the fly ash can be widely used in many fields, such as cement raw materials, water conservancy projects, concrete products and many other fields, which not only solves the problem of fly ash pollution, but also realizes the comprehensive utilization of solid waste.

Main Characteristics of Fly Ash Drying Machine

♠ High degree of automation, small floor area, convenient and stable operation.

♣ Strong overload resistance, large processing capacity, less fuel consumption and low drying cost.

♥ Equip with special dust removing equipment, which is anti corrosion, high temperature resistance and anti condensation, effectively improving the service time of dust remover.

♦ Adopt “self-aligning roller device”, which makes the supporting roller and rolling ring in linear contact, thus greatly reducing the wear and power loss.

♠ The required final moisture content can be easily adjusted according to users’ requirements

Coal Ash Drying Machine Wide Application

The coal ash drying machine is mainly used for drying industrial dust and waste residues such as fly ash, slime, lignite, raw coal, desulfurization gypsum, phosphogypsum, titanium gypsum, sludge, compound fertilizer and other materials with large water content and certain viscosity. Fly ash dryer is widely applied in mineral processing, building materials, metallurgy, chemical industry and other industries.

Fly Ash Drying Machine Working Principle

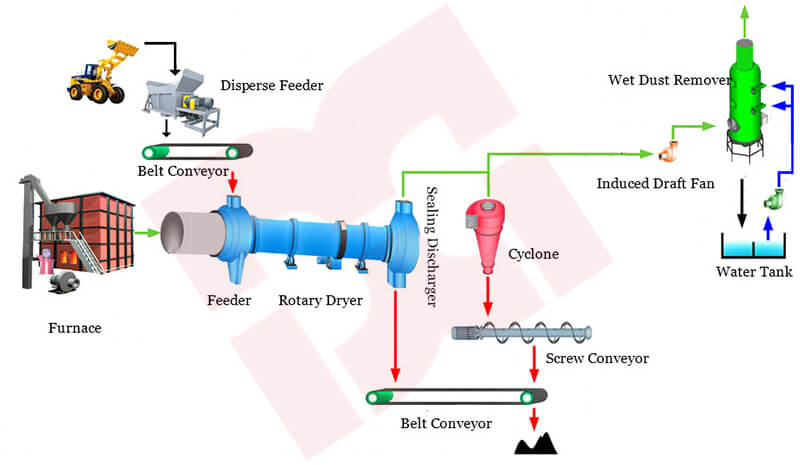

The fly ash is conveyed to the feeder by the belt loader, and then delivered to the drying drum. The fly ash entering the dryer falls on the front end of the drum, then guided to the middle area of the rotary drum under the action of the material guiding plate. The fly ash is evenly dispersed and fully contacted with hot air under the overturning of the uniformly distributed lifting plate in the drying drum, so as to achieve the drying purpose of heat and mass transfer. The dried fly ash is discharged at the end of the drum through the discharger. The exhaust gas is drawn out of the drying machine by the induced draft fan and enters the dust remover for purification.

Fly Ash Dryer Working Video

Fly Ash Dryer Technical Parameters

Model | Capacity | Initial Moisture | Final Moisture | Power | Floor Area | Max. Inlet Temperature |

DDFHG19165 | 12–16T/h | 20±5% | ≤5% | 109kw | 7m*25m | 700~750℃ |

DDFHG2218 | 16–20T/h | 128kw | 8m*30m | 700~750℃ | ||

DDFHG25195 | 20–26T/h | 143 kw | 8m*30m | 700~750℃ | ||

DDFHG28225 | 26–36T/h | 210kw | 8m*40m | 700~750℃ |