Bagasse Dryer

Bagasse Dryer Machine Introduction

Bagasse is the main by-product of sugar industry, which is the heterogeneous fiber residue left after sugarcane is crushed for sugar production. The first step of bagasse reuse is to remove its moisture. Our bagasse dryer is specially designed according to the characteristics of easy adhesion of bagasse when heated. A dispersing device is adopted in the drum of the bagasse dryer. The combination of rapid stirring drying and air drying can fully disperse the bagasse and greatly improve the contact area between materials and heat medium, which is conducive to the full drying of the bagasse.

Advantages of Bagasse Dryer Machine

1. Large processing capacity and high thermal efficiency. The thermal efficiency can reach 80% when drying the non bound water.

2. High drying intensity. The materials are highly dispersed in the air flow, the total surface area of the particles is the effective drying area.

3. Variable frequency speed regulation is adopted to control the material flow, which can easily adjust the required final moisture according to the needs of customers.

4. The outlet temperature is low, which can prolong the service life of dust removal equipment, and the next process can be carried out continuously.

5. Equipped with new energy-saving hot blast stove, high efficiency, thermal control, simple operation, and coal consumption reduction of about 60%.

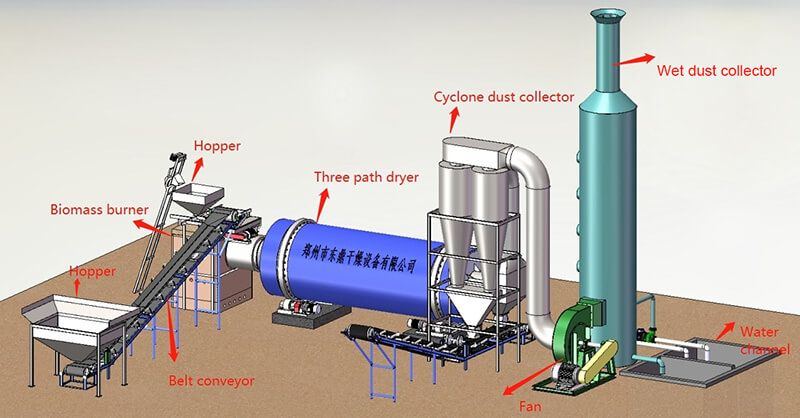

Sugarcane Bagasse Drying System

The complete bagasse drying system is consist of hot blast stove, bagasse dehydration machine, feeding device, bagasse dryer, discharging machine, induced draft equipment, transmission device, reducer, power control system, etc.

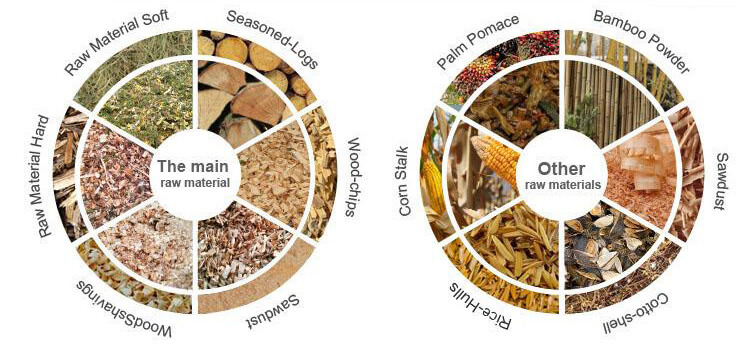

Bagasse Dryer Machine Wide Application

The bagasse dryer is widely applicable to drying bagasse, fruit dregs, beet dregs, alfalfa, brewery spent grain, crop straw, wood chips, shavings, Chinese herbal medicine, potato starch dregs, cassava dregs, etc. It is also widely used in agricultural, building materials, chemical industry, and other industries.

Bagasse Dryer Working Video

Bagasse Dryer Technical Parameters

Model | DDSG2010 | DDSG 2210 | DDSG 2510 | DDSG 2512 | DDSG 2912 |

Capacity (t/d) | 63.5-144.5 | 67.5-154.0 | 83.5-193.0 | 100-227.0 | 120.0-268.0 |

Vaporization (t/h) | 1.850 | 1.976 | 2.427 | 2.912 | 3.432 |

Initial moisture (%) | 35~60 | 35~60 | 35~60 | 35~60 | 35~60 |

Final moisture (%) | 12~15% | 12~15% | 12~15% | 12~15% | 12~15% |

Drying temperature | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 |

Power(kw) | 78 | 85 | 110 | 125 | 135 |

Weight (kg) | 25000 | 27000 | 35000 | 38000 | 43500 |

Plant area (㎡) | 8m×18m | 10m×18m | 10m×18m | 10m×20m | 10m×22m |