Flue Gas Desulfurization Tower

Flue Gas Desulfurization Tower Introduction

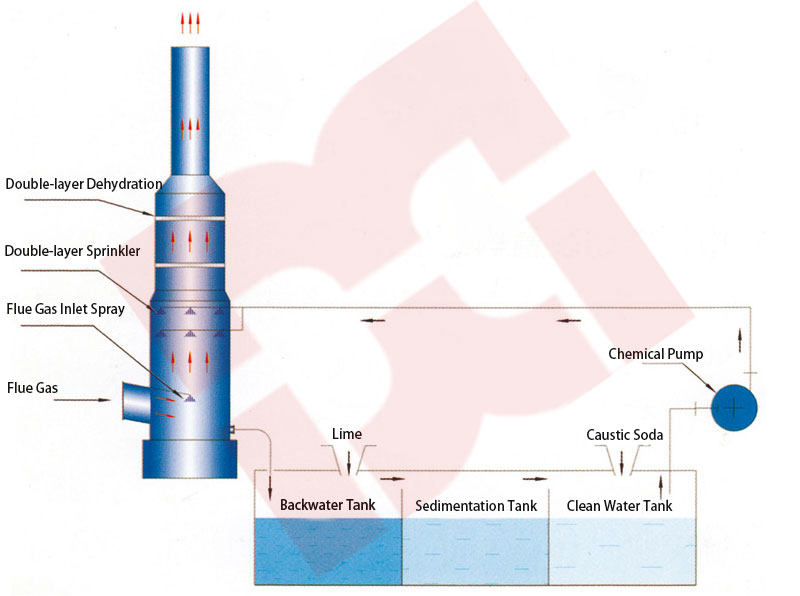

Desulfurization tower is specially used for desulfurization treatment of rotary dryer tail gas and boiler flue gas. The dual-alkali method is adopted for desulfurization. Sodium hydroxide is used as the starting desulfurizer to absorb SO2, and lime liquor is used for reduction and regeneration. The regenerated desulfurizer is recycled without waste water discharge. The desulfurized flue gas enters the mist eliminator to remove the moisture entrained in the flue gas and is discharged through the chimney at the top of the tower. The desulfurized liquid that has absorbed SO2 flows into the regeneration tank, where it is regenerated with the newly added redemption water. After reaction, the desulfurization liquid flows into the sedimentation regeneration tank for sedimentation. When the desulfurized liquid in one sedimentation regeneration tank is full, it will switch to another sedimentation regeneration tank. After sedimentation and regeneration, the desulfurized liquid will be pumped into the desulfurization tower for recycling.

Flue Gas Desulfurization Equipment Characteristics

♠ Different resins can be selected as substrates according to different media and temperature.

♣ GRP pipe: good corrosion resistance, no need for thermal insulation, greatly reducing costs.

♥ Small density, equivalent to 1/4 of steel, but its tensile strength and bending strength are similar to steel, with high strength and low weight.

♦ Low thermal conductivity, only 1/100 of steel, or even lower.