Wood Chips Dryer

Wood Chip Dryer Introduction

Wood chip is a kind of biological fiber organic matter with a water content of about 50%. The triple pass wood chip dryer is specially designed and manufactured for the drying of various wood materials, such as wood chips, wood shavings, wood bark, sawdust, etc. After drying, the water content of wood chips is generally 10-15%, which can be used for carbon production, boiler combustion, biomass pellet plant, gasification and power generation.

Advantages of Wood Chips Dryer Machine

* The self insulation thermal efficiency of the cylinder is more than 70%, twice than that of the traditional single cylinder dryer.

* A variety of circumferential material lifting plates can effectively control the drying time and ensure good drying effect.

* Equip with new energy-saving hot air stove, high efficiency, low energy consumption, simple operation, the coal consumption reduced by about 60%.

* Double supporting roller device is adopted and driven by large chain wheel, which not only ensures the stability of drum operation, but also saves operating costs.

* The final moisture content can be easily adjusted according to users’ requirements.

Wide Application of Wood Chips Dryer

The wood chips drying equipment is specially designed and manufactured for drying sawdust, shavings, rice husk, distillers’ grains, tea leaves, dehydrated vegetables, fruit waste, bean dregs, crop stalk, grass, straw, potato vine, peanut vine, etc. It is widely used in biomass, non-metallic mining, chemical industry, environmental protection, feed, agriculture, forestry and other industries.

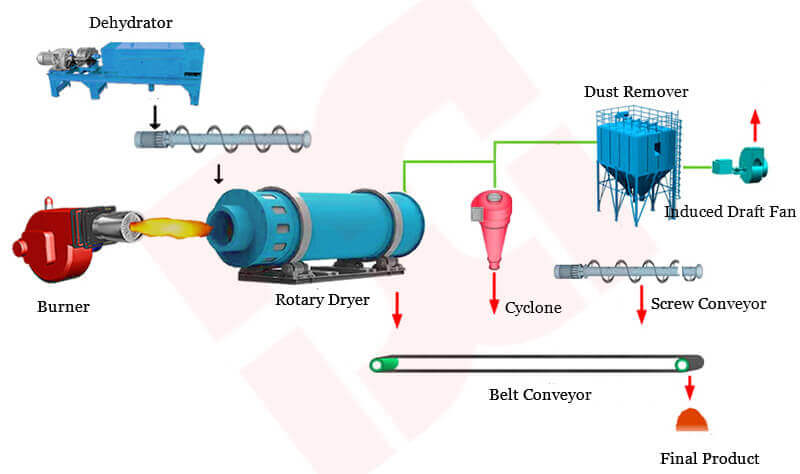

Complete Wood Chips Drying System

The complete wood chips drying system is mainly composed of crushing machine, hot blast stove, feeding and discharging device, rotary drum dryer, cyclone, dust remover, transmission device, reducer, electric control system, fan, induced draft fan, etc.

Wood Chips Dryer Working Video

Wood Chips Dryer Technical Parameters

Model | DDSG2010 | DDSG 2210 | DDSG 2510 | DDSG 2512 | DDSG 2912 |

Capacity (t/d) | 63.5-144.5 | 67.5-154.0 | 83.5-193.0 | 100-227.0 | 120.0-268.0 |

Vaporization (t/h) | 1.850 | 1.976 | 2.427 | 2.912 | 3.432 |

Initial moisture (%) | 35~60 | 35~60 | 35~60 | 35~60 | 35~60 |

Final moisture (%) | 12~15% | 12~15% | 12~15% | 12~15% | 12~15% |

Drying temperature | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 | 270℃±3 |

Power(kw) | 78 | 85 | 110 | 125 | 135 |

Weight (kg) | 25000 | 27000 | 35000 | 38000 | 43500 |

Plant area (㎡) | 8m×18m | 10m×18m | 10m×18m | 10m×20m | 10m×22m |